DODUCO manufactures precision stamped parts incorporating electrical contact functions. These stamped parts can be galvanically coated at DODUCO Solutions, produced from semi-finished contact materials, have bondable surfaces or can be mounted or pre-assembled. Depending on customer requirements we supply stampings as individual parts, in strip form, as combs or in blister package strips.

We take care of the increased requirements in terms of technical cleanliness with a class 7 clean room. In particular, we can fully meet the cleanliness and particle requirements of companies in the automotive industry or switch technology in production and packaging.

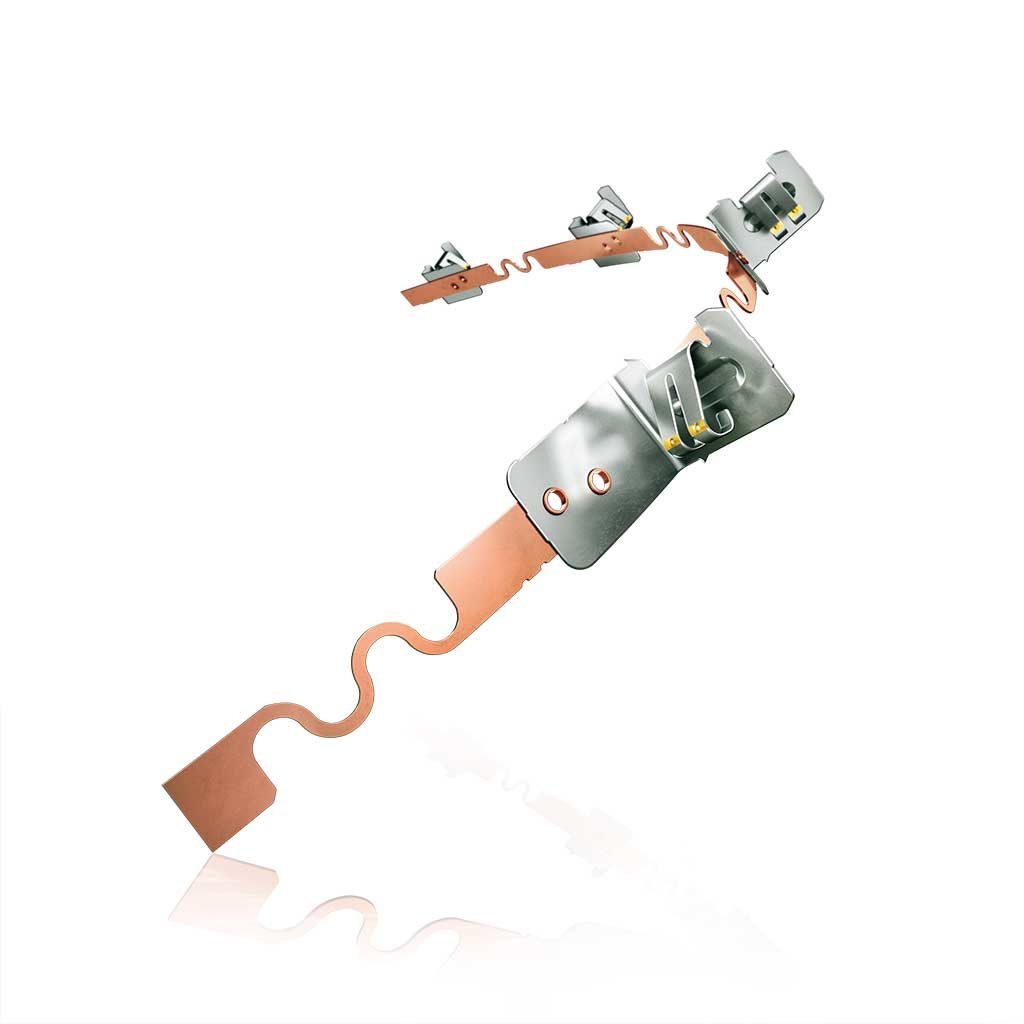

Pre-assembled- or pre-mounted-stamped parts consist of a minimum of two base materials. The attachment of the individual stamping grids is performed by riveting and coining in the stamping tool. In order to ensure a lasting high conductivity of the joint an additional welding step is often employed.

Depending on the requirements for the pre-mounted parts different properties of the single components are combined. High electrical conductivity of one material, for example, is combined with the good elastic spring behavior of the second one. Stamping parts from step milled dual gage base materials can quite often not fulfill the diverging technical requirements. This is mostly the case if higher requirements on spring properties are specified.

Pre-mounted stamped parts can also be used as functional parts for non-electrical applications. As a contact component however at least one of the base materials has either a electroplated functional coating or contact material is attached to one substrate material by cladding, welding or rivet-staking.

Electroplating processes allow the selective deposition of very thin layers within tight manufacturing tolerances. The usually high internal hardness and mechanical wear resistance of electroplated layers is advantageous in many applications. Since even thin layers have mostly a low porosity, these deposits serve also as protection against corrosion.

The type of deposit, its chemical and physical properties as well as layer sequences and thickness are defined by the application’s mechanical and electrical requirements. Electroplated deposits consist mostly of pure gold, hard gold, silver, palladium-nickel, copper, nickel and nickel-phosphorus. Tin and tin-lead can be applied in strip form also by hot-dipping.

Pre-stamped strips are selectively electro-plated using immersion, strip and spot-plating or by the process of brush-plating. Stamping combs or discrete stamped parts are coated completely or selectively by immersion electroplating or all-over in bulk by barrel plating.

You can find more information about our coating processes under “Coating technology”.

Our contact springs for the automated fitting of printed circuit boards come in blistertape. So the packaging is suitable for high-series manufacturing with off-the-shelf SMD pick-and place machines. DODUFLEX provides extremely high contact reliability through bifurcated contacts, AuCo-coating and overload protection. This contact spring is already in successful use in fields such as medical technology and white goods. It is available on short term without tool costs.

For reliable connections in hybrid frames and printed circuit boards DODUCO manufactures stamped parts with flexible press-fit zones according to DIN EN 60352-5. The Elo-Pin ® was developed in following the latest know-how of insertion technology. Based on high elasticity it exhibits low insertion forces and high holding power.

The stamped pins include the proven needle-eye design and precision formed zone edges resulting in a gastight connection without any shaving effects during the actual insertion process. These press-fit zones have shown their superior function also for the high temperature engine room environment in automotive applications.

DODUCO has for many years the in-house capability for the manufacture of AlSi clad strip and its subsequent processing as stamped components. For special stamping parts DODUCO has further developed surfaces for contacting semiconductors through wire bonding.

For most customer applications the reliability of the bond connections over extended periods of time and under demanding environmental conditions are of highest importance.

For the design of our high performance stamping tools we use 3D CAD (Creo) and employ modular concepts. Depending on the requirements, cutting inserts are constructed of carbide or special tool steels. Our modern and well equipped tool shop supports advanced technological standards.

We integrate into our progressive dies additional functions such as multiple thread cutting, multiple in-die rivet staking and also pre-mounting of stamped parts in strip form. The flawless operation of our dies is monitored and controlled through optical and structure-born sound sensors.

The range of our high capacity stamping presses allows the use of strip thicknesses from as low as 0.03 mm (.0012”) to about 3.0 mm (.118”) and with a width of up to 180 mm (about 7.0”). Our maximum stamping speed range up to 1,800 strokes/min. The carrier materials – usually Cu-based or stainless steel materials – are processed from “master coils” in reel-to-reel, or into combs or discrete stamping parts. To ensure the surface cleanliness of precision stamped parts we use vanishing oils for the tool lubrication or integrate cleaning and degreasing into the stamping operations.

DODUCO Solutions GmbH

Im Altgefäll 12

75181 Pforzheim

Germany

DODUCO Solutions GmbH is based in the German town of Pforzheim where it develops products and technologies for metal coating, strips and stamping. Our products and services are used in a wide range of applications in mechanical and plant engineering, the electrical and automotive industries and the renewable and alternative energy sector. By linking up numerous technologies across a series of compound tools, we are able to offer total business solutions at the highest level.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information